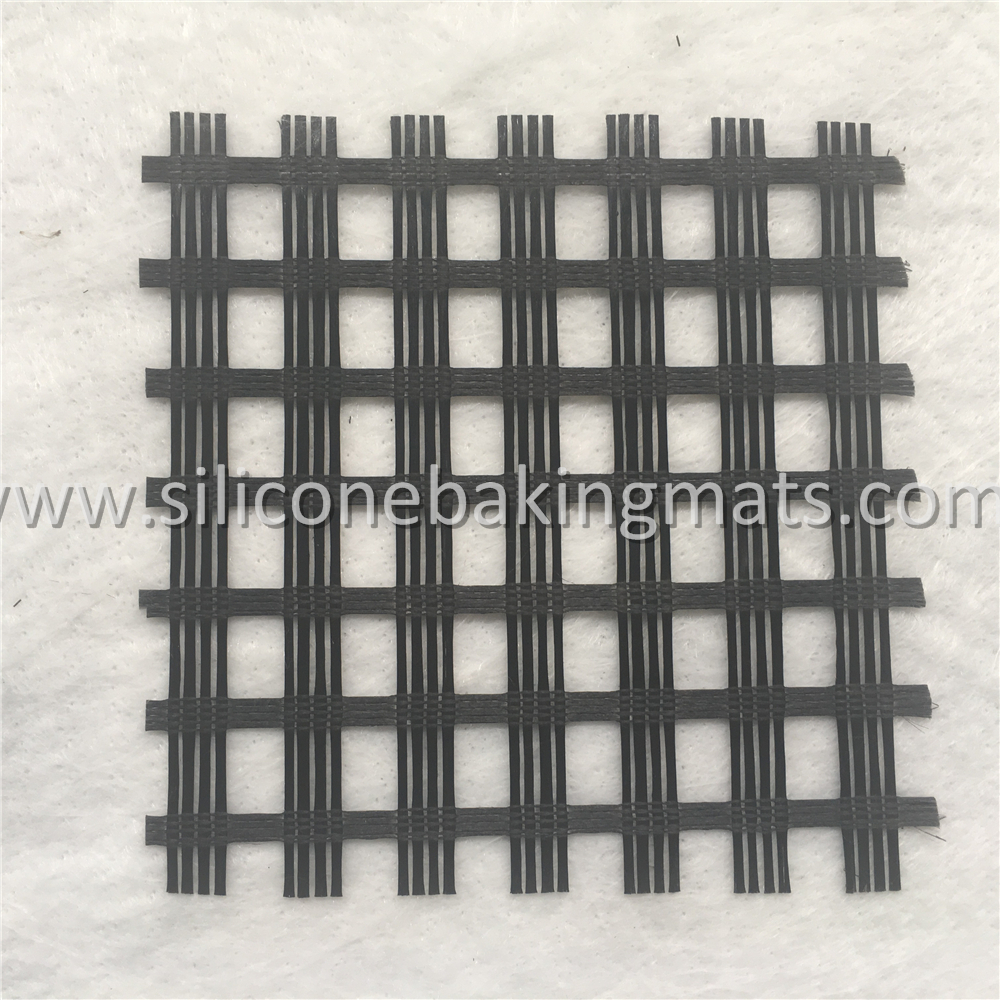

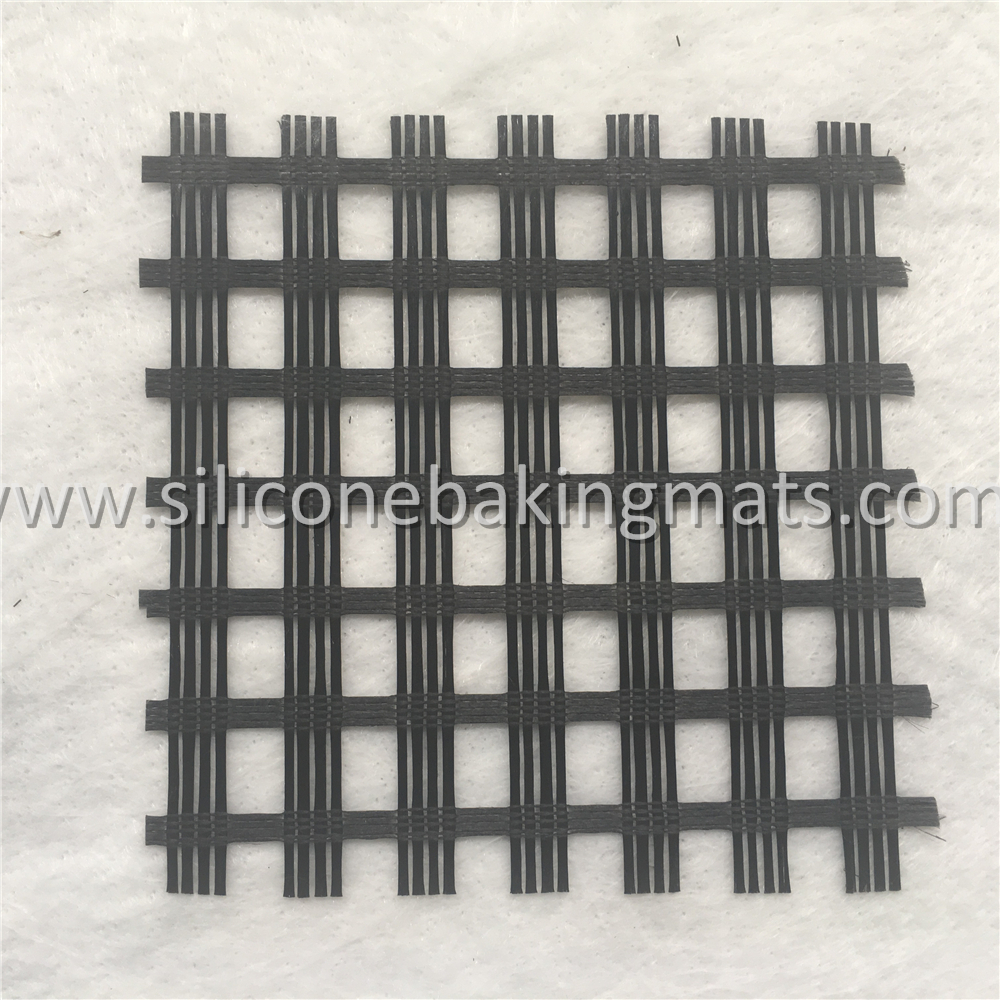

Fiberglass Geogrid For Pavement Stabilization have a square or rectangular open mesh form. The open structure facilitates aggregate interlock between paving courses, restrains lateral movement of the aggregates, and thus greatly decreases shear potential which is common with paving fabrics. The open grid structure enhances through-hole bearing capacity and allows more stress to transfer to Geogrid For Pavement Stabilization by means of the interlocking aggregates of the asphalt layers. Glass Fiber Geogrid For Pavement Stabilization is widely used in road, brige and tunnel construction. Fiberglass Grid For Pavement Stabilization is cost effective and eco friendly.

Certificates: ISO9001, CE, ITB

Features and Benefits:

• Lowers maintenance costs

• Repairs severely cracked roads and postpones complete reconstruction

• Dramatically extends the life of roads, runways and parking lots

• Open aperture design promotes aggregate interlock between paving courses, greatly decreasing shear potential that is common with paving fabrics

• High stiffness, high modulus of elasticity, low elongation

• Effective bonding of grid during installation to leveling course with patented adhesive backing (standard practice of use of tack coat is recommended to enhance or promote bonding between lifts of ACC layers)

• Ease of constructability allows for Fibgrid installation and immediate placement of overlying pavement

• Suitable for all types of asphalt mixes.

• Minimizes both thermal and stress related reflective cracking.

• Reduces pavement rutting under high ambient temperatures and intense wheel loads.

• Increases the fatigue life of pavements with weak foundations.

• Extends pavement life.

• Provides cost benefits by increasing pavement life cycle.

• Fast, easy installation and recyclable.

• Reduces overlay thickness to a minimum of 50 mm.

Applications:

1. Airport runways, taxiways, roads, bridges, parking lots, jointed concrete highways to control reflective cracking.

2. High traffic pavement to control of rutting.

3. New highway construction, and other road maintenance/repair jobs to improve pavement life.

Technical Date:

| Fiberglass Geogrid Technical Data |

| Specification | Tensile Strength (kN/m) | Elongation | Mesh size (mm x mm) | Width (m) | Roll Length (m) | Elastic Modulus (Gpa) | Temperature Resistance |

| Warp | Weft | Warp | Weft |

| FG2525 | ≥ 25 | ≥ 25 | ≤ 3 | ≤ 3 | 12.7x12.7 25.4x25.4 30x30 40x40 50x50 | 1 1.5 2 2.5 3 4 4.5 5 6 | 50 100 150 200 300 400 500 600 | 76 | -100°C-280°C |

| FG3030 | ≥ 30 | ≥ 30 | ≤ 3 | ≤ 3 |

| FG4040 | ≥ 40 | ≥ 40 | ≤ 3 | ≤ 3 |

| FG5050 | ≥ 50 | ≥ 50 | ≤ 3 | ≤ 3 |

| FG6060 | ≥ 60 | ≥ 60 | ≤ 3 | ≤ 3 |

| FG8080 | ≥ 80 | ≥ 80 | ≤ 3 | ≤ 3 |

| FG9090 | ≥ 80 | ≥ 80 | ≤ 3 | ≤ 3 |

| FG100100 | ≥ 100 | ≥ 100 | ≤ 3 | ≤ 3 |

| FG120120 | ≥ 120 | ≥ 120 | ≤ 3 | ≤ 3 |

| FG150150 | ≥ 150 | ≥ 150 | ≤ 3 | ≤ 3 |

| FG180180 | ≥ 180 | ≥ 180 | ≤ 3 | ≤ 3 |

| FG200200 | ≥ 200 | ≥ 200 | ≤ 3 | ≤ 3 |

| FG300300 | ≥ 300 | ≥ 300 | ≤ 3 | ≤ 3 |

| FG400400 | ≥ 400 | ≥ 400 | ≤ 3 | ≤ 3 |

| Physical and Chemical Stability | Good |

| Pressure Sensative Glue | Available |

| Coating Material | Modified Asphalt Polymer, Acrylic Acid Polymer, SBR or PVC |

| Resin Content (%) | More than 20% |

| Composited or Sewed with Non-Woven Fabric or Geotextile | 25g, 30g, 40g or 50g/m2 PP no-woven fabric with one side or two side by pressure sensative glue or warp knitted 100g/m2, 120g/m2 or 140g/m2 Polyester continous filament needle punched geotextile by warp knitted |

Packages:

1. Each roll per PE or Polybag or woven bag, then in container. Colourful label can be available upon request.

2. Each roll per PE or Polybag or woven bag, then on pallet

3. Custom package can be available.

How to install Fiberglass Geogrid

1. Prepare the Surface

• Complete all crack sealing, pothole filling, base repairs, leveling course applications, etc.

• Surface must be dry, clean and dust-free.

• The road surface temperature must be between 5°C* (40°F**) and 60°C (140°F). On asphalt surfaces less than 24 hours old, the surface temperature must be between 5°C (40°F) and 46°C (110°F). Local guidelines should be followed for paving temperature range.

2. Install Fibtex Fiberglass Geogrid

• Load roll onto front of tractor. Always load the red colored end of the core on the right side of the installation vehicle to allow placement of the mesh with the self-adhesive side down.

• Roll only with rubber-tired roller to activate adhesive. Roller must be kept clean.

• Apply tack coat per project requirements and pave once fully cured.

NOTE: Fibgrid can also be installed manually.

3. Pave

• The surface course of asphalt can be placed immediately after Fibgrid is installed. There are no disruptions or delays to normal paving operations.

• Minimum 75-150 mm (3-6") overlap is required at end of roll joints. Minimum 25-50 mm (1-2") overlap is required for longitudinal joints.

Product Categories : Geosynthetics Series > Fiberglass Geogrid